News

What is the function of the spiral sludge filter press?

2023-01-14

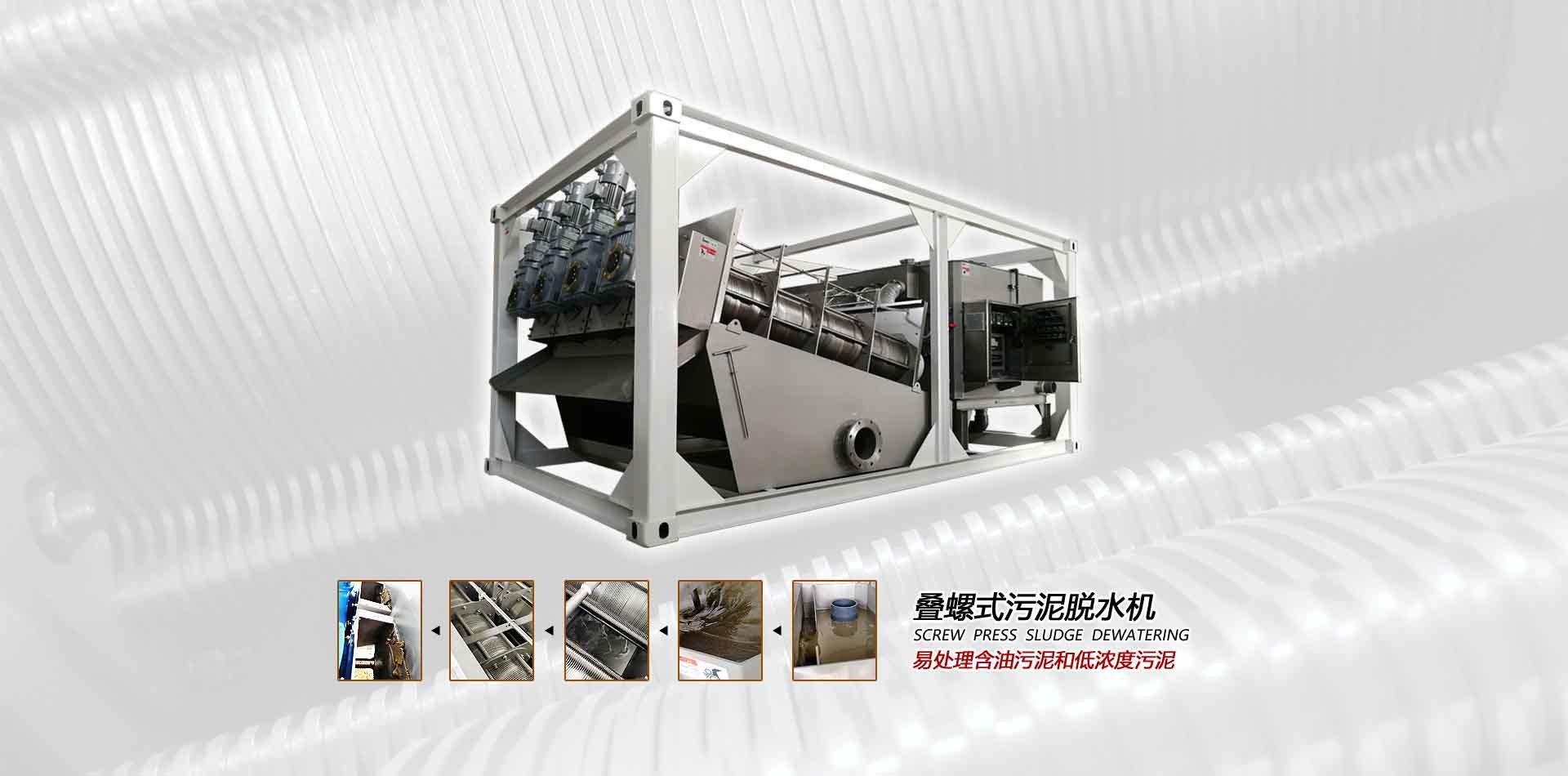

As a new type of sludge dewatering equipment, the stacked sludge filter press is not familiar to many users in the industry. Many users will have questions about the function of the stacked sludge filter press? Here is a detailed introduction. I hope it can bring you good help.

The spiral sludge filter press is a kind of sludge dewatering equipment. In today's increasingly demanding wastewater treatment, wastewater biochemical treatment is a common wastewater treatment process. Sludge will be generated after treatment. The spiral sludge filter press is the equipment for treating this part of biochemical sludge. It can also be seen in many places. Compared with sewage plants, food plants, chemical plants, paper mills, printing and dyeing plants, slaughterhouses and other industries, the pollutant indicators in sewage are very high and can only be discharged after biochemical treatment. As we all know, the mechanical treatment effect of some traditional filter presses on biochemical sludge is not good and the efficiency is not high. In the process of processing, various problems often occur, which seriously restrict the development of enterprises. The stacked sludge filter press is introduced into the domestic market as a biochemical sludge treatment. Seeing this, I believe many users will understand what the functions of the screw stacker are. It is a kind of equipment to replace the pressure filter for biochemical sludge treatment. At present, the output of sludge is increasing, and sludge cannot be easily disposed and stacked at will. Thickening and dewatering shall be carried out by screw stacker to realize solid-liquid separation and harmless treatment of sludge.

In addition, the pressure filter for stacked sludge is a new type of equipment developed in recent years. The integral lead screw shaft is composed of dynamic and static rings. Horizontal and vertical full extrusion, the water content can reach below 85. The outstanding features are less power consumption, high degree of automation and less land occupation. Therefore, in the process of operation, it is certainly more power saving than the traditional sludge filter press. The spiral sludge filter press is easy to operate and more reliable without contact between people and sludge. Longer life than belt type, saving electricity and water. Free water can also be separated under the action of gravity to form stagnant sludge, which is then sandwiched between the upper and lower mesh belts. Under the action of the force, the sludge is further squeezed to achieve the purpose of dehydration, and then the sludge is separated from the water to form a filter cake for discharge, which is convenient for storage and transportation. The spiral sludge filter press adopts low pressure filtration and high pressure pressing, which can greatly shorten the entire filtration cycle. TPE elastomer is also used, and the filtering pressure can reach 25MPA, which greatly reduces the water content, saves the drying cost, and improves the output.

The above article is about the function of the spiral sludge filter press. I don't know if you understand it. If you still don't understand something, you can consult at any time. Remember to pay more attention to the website so as not to miss the wonderful content.

Latest News

Contact

National after-sales telephone: 086-523-88858618

Sales hotline: 8618052658218

Email: info@diawee.com

Address: No. 88 Xingjiang Road, Jiangyan District, Taizhou City, Jiangsu Province

Copyright:Jiangsu Diawee Environmental Protection Technology Co., Ltd

Language

Language