News

Size selection and structure of screw stacking dehydrator

2021-11-08

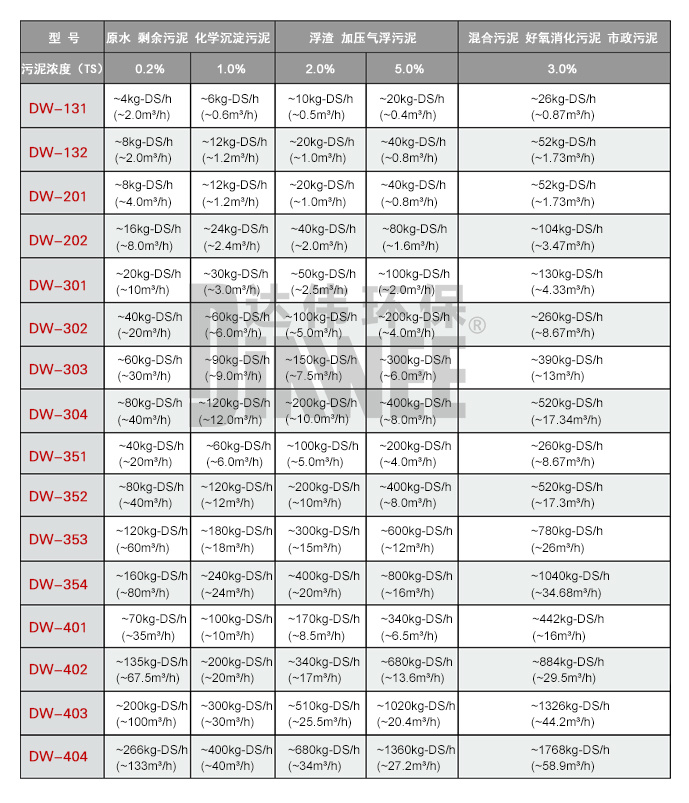

The Dawei stacked snail dehydrator is equipped with a specially designed stacked snail body, which is exquisite in design and has a variety of product models, ranging from a super small dehydrator with a processing capacity of 0.5kg-DS/h to a super large dehydrator with a processing capacity of 1320~1360kg-DS/h. The size span ranges from 1920mm * 75mm * 989mm for a small dehydrator to 5300mm * 3180mm * 2400mm for a large dehydrator. Be able to provide the most appropriate technical solutions according to the actual handling capacity needs of customers.

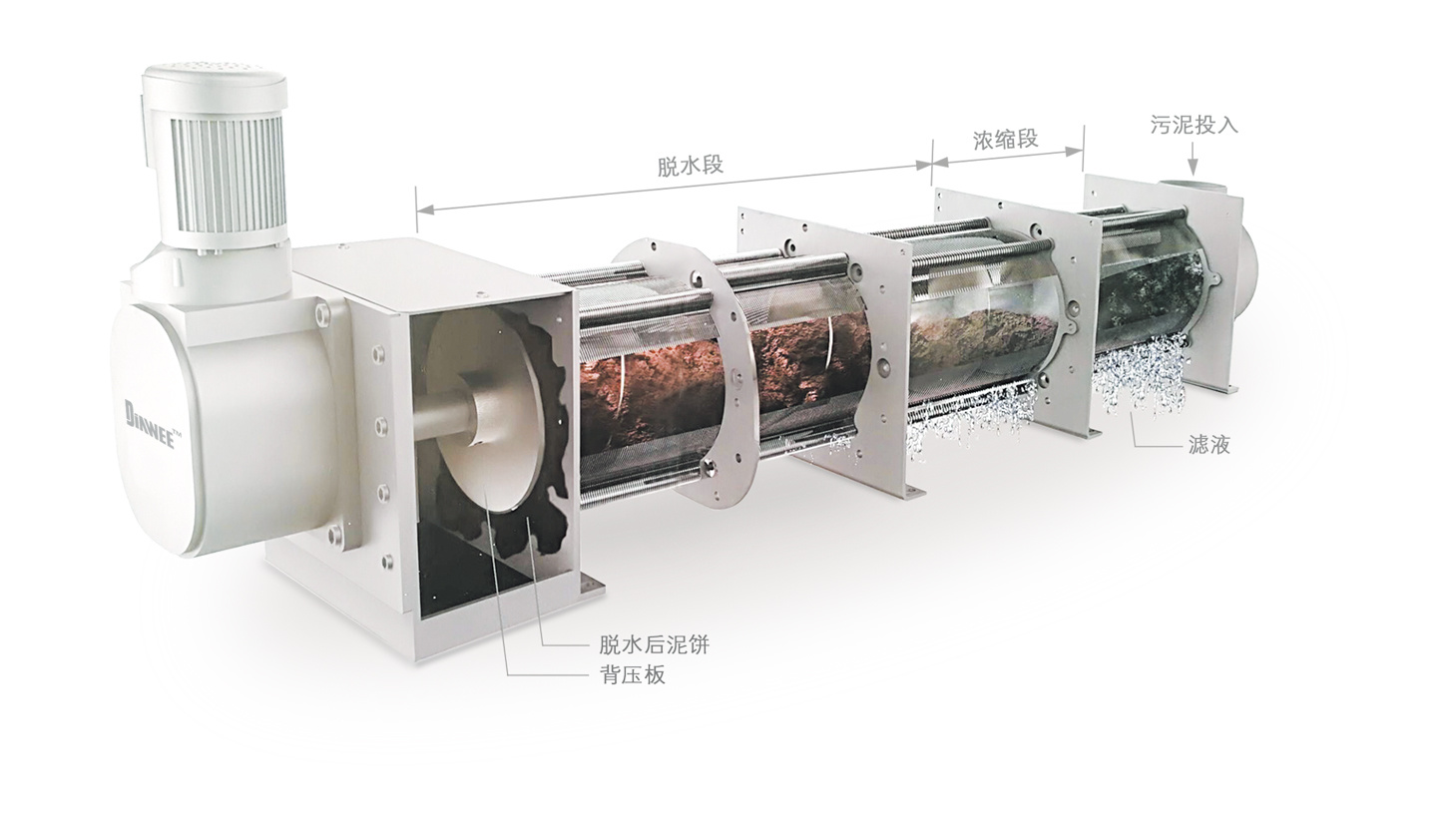

The screw stacking dehydrator consists of metering tank, sludge pump, flocculation mixing tank and dehydration main body. The dehydration process is fully automated by the electric control cabinet (or PLC), which is linked with the dosing equipment and sludge conveying equipment to achieve 24-hour automatic operation. The main body of the dehydrator is composed of a moving ring, a fixed ring and a spiral shaft. There is a movable ring in the middle of every two fixed rings, which increases the overlap, and the lead screw shaft passes through it.

The mixed liquid flows into the filter cartridge of the screw stacking dehydrator through the feed port, and the filter cartridge is composed of fixed laminations and movable laminations alternately. Driven by the spiral shaft, the material moves towards the end of the discharge opening. As the screw pitch between the spiral shaft and the blade gradually decreases, the pressure on the sludge gradually increases. Under the effect of differential pressure, the sludge begins to dehydrate, and the free water flows out from the filter gap between the movable plate and the fixed plate.

As the diameter of the spiral shaft is larger than the diameter of the movable plate, when the spiral shaft rotates, it drives the movable plate to rotate together. The dehydrator relies on the relative movement of the movable plate and the fixed plate to realize the self-cleaning function and prevent the filter gap from being blocked. The completely dehydrated mud cake is discharged from the discharge port under the push of the spiral shaft. Since there is always relative movement between the fixed plate and the movable plate, some small sludge particles are always squeezed out of the gap with water.

In order to prevent overflowing sludge particles from depositing on the surface of the filter cartridge, an automatic water spraying washing system is set up to spray clean the surface of the filter cartridge regularly to keep the surface of the filter cartridge clean. The obtained mud cake has a moisture content of 78% - 85%, a solid recovery of more than 95%, a screw shaft speed of 2-3 r/min, no vibration, no noise, and can be directly dehydrated at low temperature.

The outlet water of the screw extractor has a certain turbidity. As the filtered water returns to the biochemical system, the filtrate is allowed to have a certain turbidity. The clearance between the fixed plate and the movable plate is fixed at the factory and cannot be adjusted at will. The water content of the filter mud cake can be adjusted by adjusting the clearance of the back pressure plate and the feeding amount.

Dawei stacked snail dehydrator has small floor area, self cleaning, non clogging, no noise, low energy consumption, fully automatic unattended, stable and reliable, saving infrastructure costs, wide application range, and is better at handling low concentration sludge. Welcome customers to inquire!

Latest News

Contact

National after-sales telephone: 086-523-88858618

Sales hotline: 008615061040941

Email: ailian@bluepurell.com

Address: No. 88 Xingjiang Road, Jiangyan District, Taizhou City, Jiangsu Province

Language

Language