Waste heat type closed belt modular sludge drying system

Product Category

key word:

Detailed Description

Sludge is made of suspended solids in wastewater that are agglomerated and coagulated in different ways, with loose structure, irregular shape, very high water content in specific surface area and porosity, and poor dewatering. The water in sludge has different forms of existence and thus the difficulty of removing water is also different. The main purposes of sludge treatment are:1. to reduce the volume of sludge, i.e. to reduce the water content of sludge, to create conditions for sludge transport, digestion, dewatering and comprehensive use, and to reduce the volume of sludge before final treatment.2. to sanitize and stabilize sludge, which contains a large amount of organic matter, various pathogens and other harmful substances (e.g. heavy metals), and if not stabilized will definitely become "Secondary pollution" leads to environmental pollution and spread of germs 3. Improving the composition and some properties of sludge through treatment in order to facilitate sludge resource utilization. The principles of sludge treatment are reduction, stabilization, non-hazardous and resourcefulness, and the most important operation in reduction and stabilization is the removal of water from sludge.

The sludge low-temperature dryer adopts heat pump low-temperature dehumidification to evaporate the water in sludge, and then carry out closed condensation dehumidification ﹑ without losing heat in the process of dehumidification, without odor and dust emission, automatic operation, and large drying processing capacity. It provides a more convenient way of sludge treatment for the majority of enterprises, and further reduces the sludge treatment cost and transportation cost for enterprises.

Optional kits are inorganic nano-membrane ceramics, PH adjustment device, and oil removal equipment.

| Closed type low temperature dryer | ||

| Stabilization and non-pollution | Reduction | Resourcefulness |

| The effective sterilization of dry mud reaches 90%, stable in nature and without secondary pollution. | It can dry 83% water content sludge to 10%, with 80% reduction. | Dried sludge pellets can be gasified, blended, incinerated, and can be used as biofuel, green soil, and for cement plants/building materials, etc. |

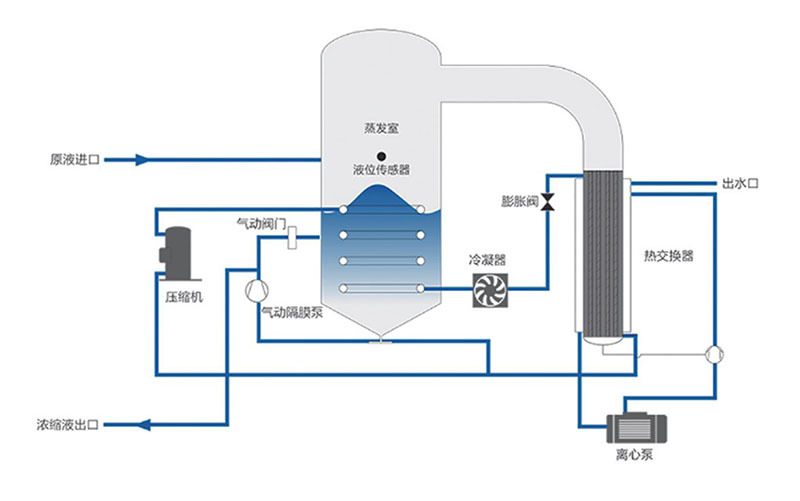

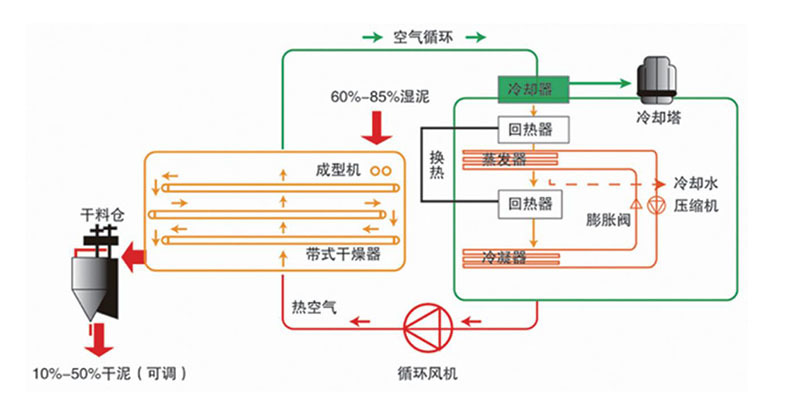

Dryer principle

Using the heat pump system, the wet air from the drying chamber is cooled down and dehumidified by the evaporator, and at the same time heated up and reheated by the condenser to dry hot air and sent into the drying chamber, so that the water in the sludge is separated through air circulation and discharged into the cesspool with the evaporator condensate.

Dryer features

☆ Deep dewatering and reduction infinite

Multi-stage energy integrated processing, powerful drying reduction capacity, reduction up to 80% or more, overturning the traditional drying method exists in the high moisture content of dry mud, the technical bottleneck of weak reduction capacity.

☆ High efficiency dehumidification cost free

Several invention patents innovation design, high efficiency and energy saving, dewatering per dry watt power can reach more than 4kg per hour, reducing the cost of more savings. More than 50% cost saving than traditional low temperature drying equipment.

☆ Closed cycle environment friendly

It adopts closed cycle drying design, no odor emission, no need to install expensive deodorization system at secondary cost, and can be installed directly in the plant for centralized sludge disposal, low COO of condensate, and simple treatment.

☆Cold and heat balance energy saving and consumption reduction

Adopting comprehensive energy application technology, heat and cold balance treatment and utilization, no heat loss, system working energy efficiency is more outstanding than the open type drying equipment with continuous moisture dissipation and heat supply.

☆ Heat pump drying without dust and explosion

The heat pump is fully enclosed low-temperature drying operation, safe and environmental protection, no dust and explosion hazards, the discharge temperature is lower than 48C, no secondary cooling, and can be stored directly.

☆ Complete varieties of drying flexibility

The drying capacity of the product is from 3kg ~ 100kg per hour to meet the drying requirements of different places, while the product is designed for comprehensive anti-corrosion to ensure the quality of the product and a longer service life.

☆Free setting of drying degree adjustable

The drying time and drying temperature can be set freely to meet the requirements of the drying moisture content that is not needed, and the degree of control drying is more accurate, solving the difficulties of the traditional drying time and the degree of drying imprecision.

| Model OML- | D5000HSII | D1000SII | D15000SII | D20000SII | D2500SII | D3000SII | D35000SII |

| Standard water removal kg/24h | ~5000 | ~10000 | ~15000 | ~20000 | ~25000 | ~30000 | ~35000 |

| Water removal kg/h | ~208 | ~416 | ~624 | ~832 | ~1040 | ~1248 | ~1458 |

| Operating power kW | 13 | 26 | 39 | 52 | 65 | 78 | 91 |

| Standard heating power kW | 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 |

| Hot water flow rate m3/h | 8.6 | 17.2 | 25.8 | 34.4 | 43 | 51.6 | 60.2 |

| Standard cooling power kW | 180 | 360 | 540 | 720 | 900 | 1080 | 1260 |

|

Cooling water flow rate m3/h (Temperature difference 15℃) |

13 | 26 | 39 | 52 | 65 | 78 | 91 |

| Number of modules | 1 unit | 2 units | 3 units | 4 units | 5 units | 6 units | 7 units |

| Power supply | 380V/3N~50HZ | ||||||

| Standard heating conditions | 90℃/70℃(hot water, etc.) | ||||||

| Cooling conditions | 30℃/45℃ | ||||||

| Drying temperature | 50~65℃(return air)/68~85℃(supply air) | ||||||

| Other heat source forms are available |

Flue gas waste heat, steam condensate, generator waste heat, anaerobic digestion (gas to hot water), sludge cracking gas combustion to hot water, etc. |

||||||

| Control System | Touch screen + PLC programmable controller | ||||||

| Scope of application of wet clay | Moisture content (40%~60%) (different adaptability to different moisture content) | ||||||

| Water content of dry material |

Variable frequency adjustment, moisture content (10%-60%) (different adjustment range of dry material moisture content for different water content of incoming mud) |

||||||

| Forming method | cut strips | ||||||

| Overall dimension length mm | 3910 | 6610 | 9310 | 8000 | 11250 | 14500 | 17750 |

| Dimension width mm | 2250 | 2250 | 2250 | 3150 | 3150 | 3150 | 3150 |

| Overall dimension height mm | 2480 | 2480 | 2480 | 3250 | 3250 | 3250 | 3250 |

| Structure form | Assembling | Assembling | Assembling | Assembling | Assembling | Assembling | Assembling |

| Weight | 3.1T | 5.7T | 7.8T | 8.9T | 12T | 15.2T | 17.5T |

Recommended Products

Online Mssage

Contact

National after-sales telephone: 086-523-88858618

Sales hotline: 008615061040941

Email: ailian@bluepurell.com

Address: No. 88 Xingjiang Road, Jiangyan District, Taizhou City, Jiangsu Province

Language

Language