Sludge Thickener

Product Category

key word:

Detailed Description

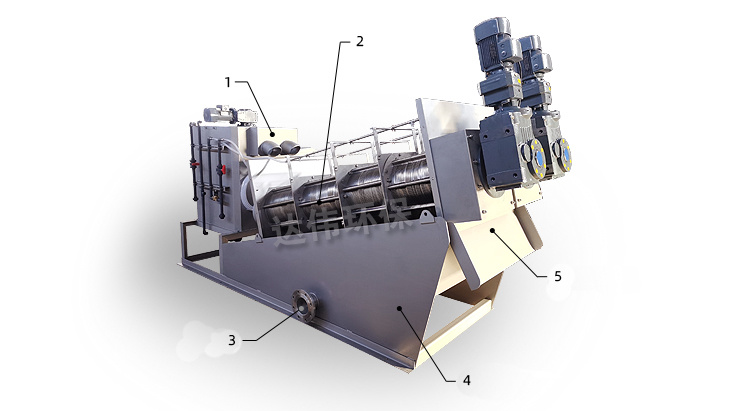

| Product Structure Analysis | ||

| 1 Flocculation mixing tank | 2 Concentration and dewatering main body | 3 Filtrate outlet |

| 4 Catch basin base | 5 Export of demineralized cakes | |

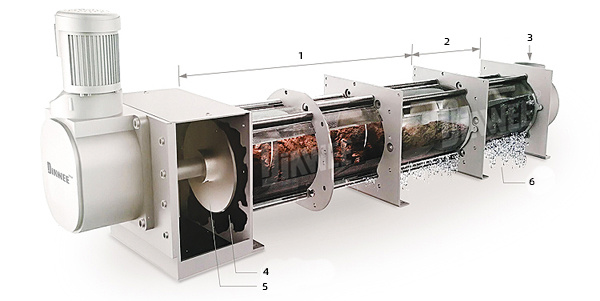

| Product Structure Analysis | ||

| 1 Dehydration section | 2 Concentrated section | 3 Sludge input |

| 4 Dehydrated mud cake | 5 Back pressure plate | 6 Filtrate |

When the equipment is running, the sludge enters the filter cartridge from the feeding port and is pushed to the discharge port by the spiral shaft blades. As the screw pitch between the spiral shaft blades gradually decreases, the pressure on the sludge also increases, and the sludge begins to dehydrate under the effect of differential pressure. The water is self-cleaning between the fixed ring and the movable ring, and the filtering gap is cleaned to prevent blockage, The mud cake is fully dehydrated and discharged from the discharge port under the propulsion of the spiral shaft.

| Installation Process | ||

| 1 Sewage pumped into metering tank | 2 Dosing flocculation mixing | 3 Concentration and dewatering of alum after flocculation |

| 4 The thickened sludge enters the dewatering section | 5 Mud cake discharge after dewatering | |

| Model | External dimensions | Net weight | Operating weight | Power | Washing water consumption | ||

| L | W | H | |||||

| DW-131 | 1920 | 750 | 989 | 205 | 300 | 0.2 | 20 |

| DW-132 | 1920 | 910 | 989 | 270 | 420 | 0.3 | 44 |

| DW-201 | 2460 | 860 | 1270 | 340 | 490 | 0.74 | 30 |

| DW-202 | 2480 | 960 | 1270 | 460 | 720 | 1.11 | 60 |

| DW-301 | 3360 | 930 | 1650 | 900 | 1310 | 1.5 | 38 |

| DW-302 | 3560 | 1245 | 1650 | 1320 | 2100 | 2.25 | 76 |

| DW-303 | 3820 | 1600 | 1650 | 1780 | 2840 | 3 | 114 |

| DW-351 | 4010 | 1150 | 2200 | 1630 | 2230 | 1.1 | 68 |

| DW-352 | 4210 | 1550 | 2200 | 2350 | 3450 | 2.75 | 136 |

| DW-353 | 4420 | 2150 | 2200 | 3360 | 4860 | 5.7 | 204 |

| DW-354 | 4640 | 2650 | 2200 | 4480 | 6080 | 9.55 | 272 |

| DW-401 | 4560 | 1250 | 2400 | 2400 | 3300 | 1.85 | 78 |

| DW-402 | 4900 | 1620 | 2400 | 3460 | 5180 | 2.95 | 156 |

| DW-403 | 5030 | 2200 | 2400 | 4500 | 7000 | 4.05 | 234 |

| DW-404 | 5300 | 3180 | 2400 | 6500 | 9610 | 5.15 | 312 |

| Model | Chemical precipitation of excess sludge from raw water | Scum pressurized floating sludge | Mixed sludge Aerobic digestion Sludge Municipal sludge | ||

| Sludge concentration (TS) | 0.2% | 1.0% | 2.0% | 5.0% | 3.0% |

| DW-131 |

~4kg-DS/h (~2.0m3/h) |

~6kg-DS/h (~0.6㎡/h) |

~10kg-DS/h (~0.5㎡3/h) |

~20kg-DS/h (~0.4㎡3/h) |

~26kg-DS/h (~0.87m3/h) |

| DW-132 |

~8kg-DS/h (~2.0㎡/h) |

~12kg-DS/h (~1.2㎡/h) |

~20kg-DS/h (~1.0m/h) |

~40kg-DS/h (~0.8㎡3/h) |

~52kg-DS/h (~1.73m3/h) |

| DW-201 |

~8kg-DS/h (~4.0㎡/h) |

~12kg-DS/h (~1.2㎡/h) |

~20kg-DS/h (~1.0㎡/h) |

~40kg-DS/h (~0.8㎡/h) |

~52kg-DS/h (~1.73㎡/h) |

| DW-202 |

~16kg-DS/h (~8.0㎡/h) |

~24kg-DS/h (~2.4㎡/h) |

~40kg-DS/h (~2.0㎡/h) |

~80kg-DS/h (~1.6㎡/h) |

~104kg-DS/h (~3.47㎡/h) |

| DW-301 |

~20kg-DS/h (~10㎡/h) |

~30kg-DS/h (~3.0㎡/h) |

~50kg-DS/h (~2.5㎡/h) |

~100kg-DS/h (~2.0㎡/h) |

~130kg-DS/h (~4.33㎡/h) |

| DW-302 |

~40kg-DS/h (~20㎡/h) |

~60kg-DS/h (~6.0㎡/h) |

~100kg-DS/h (~5.0㎡/h) |

~200kg-DS/h (~4.0㎡/h) |

~260kg-DS/h (~8.67㎡/h) |

| DW-303 |

~60kg-DS/h (~30㎡/h) |

~90kg-DS/h (~9.0㎡/h) |

~150kg-DS/h (~7.5㎡/h) |

~300kg-DS/h (~6.0㎡/h) |

~390kg-DS/h (~13㎡/h) |

| DW-351 |

~40kg-DS/h (~20㎡/h) |

~60kg-DS/h (~6.0㎡/h) |

~100kg-DS/h (~5.0㎡/h) |

~200kg-DS/h (~4.0㎡/h) |

~260kg-DS/h (~8.67㎡/h) |

| DW-352 |

~80kg-DS/h (~40㎡/h) |

~120kg-DS/h (~12㎡3/h) |

~200kg-DS/h (~10㎡/h) |

~400kg-DS/h (~8.0m/h) |

~520kg-DS/h (~17.3㎡/h) |

| DW-353 |

~120kg-DS/h (~60㎡/h) |

~180kg-DS/h (~18㎡/h) |

~300kg-DS/h (~15㎡/h) |

~600kg-DS/h (~12㎡/h) |

~780kg-DS/h (~26㎡/h) |

| DW-354 |

~160kg-DS/h (~80㎡/h) |

~240kg-DS/h (~24㎡/h) |

~400kg-DS/h (~20㎡/h) |

~800kg-DS/h (~16㎡/h) |

~1040kg-DS/h (~34.68㎡/h) |

| DW-401 |

~70kg-DS/h (~35㎡/h) |

~100kg-DS/h (~10㎡/h) |

~170kg-DS/h (~8.5㎡/h) |

~340kg-DS/h (~6.5㎡/h) |

~442kg-DS/h (~16㎡/h) |

| DW-402 |

~135kg-DS/h (~67.5㎡/h) |

~200kg-DS/h (~20㎡/h) |

~340kg-DS/h (~17㎡/h) |

~680kg-DS/h (~13.6㎡/h) |

~884kg-DS/h (~29.5㎡/h) |

| DW-403 |

~200kg-DS/h (~100㎡/h) |

~300kg-DS/h (~30㎡/h) |

~510kg-DS/h (~25.5㎡/h) |

~1020kg-DS/h (~20.4㎡/h) |

~1326kg-DS/h (~44.2㎡/h) |

| DW-404 |

~266kg-DS/h (~133㎡/h) |

~400kg-DS/h (~40㎡/h) |

~680kg-DS/h (~34㎡/h) |

~1360kg-DS/h (~27.2㎡/h) |

~1768kg-DS/h (~58.9㎡/h) |

|

|

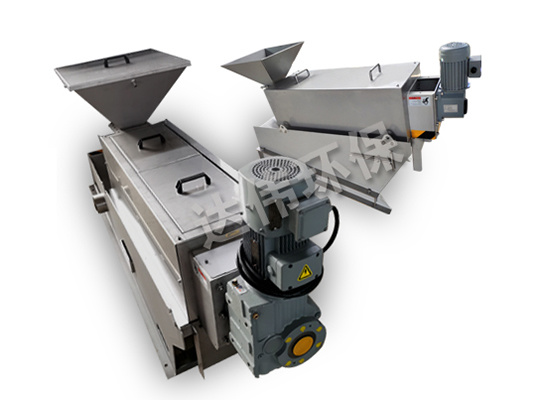

| Standard | Non-standard customized type |

|

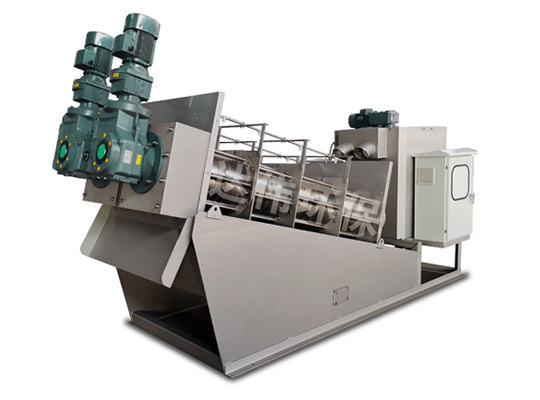

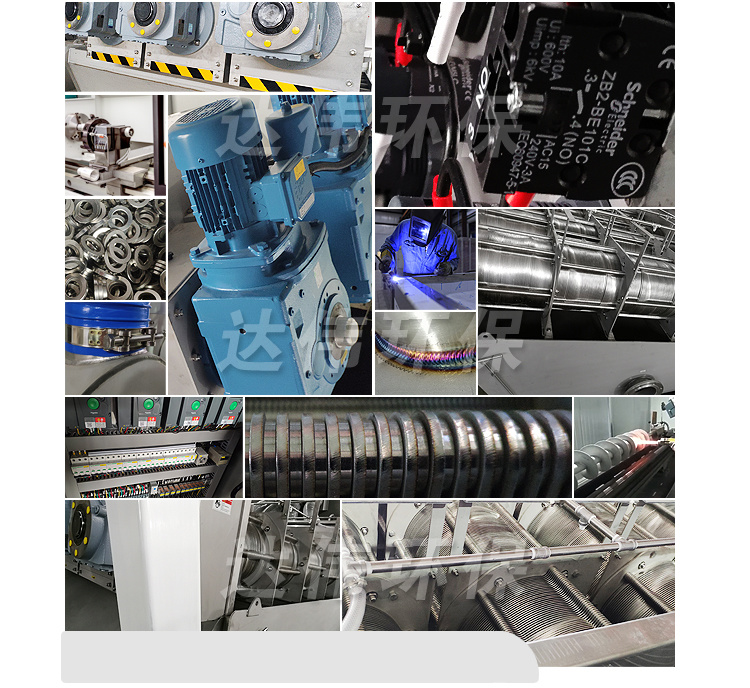

Exquisite and beautiful design, stainless steel body with longer service life Integrates flocculation, concentration, filtration and extrusion dewatering functions |

Modular structure makes it easy to maintain At the same time its flexible design and production to meet the needs of more different environments. |

Recommended Products

Online Mssage

Contact

National after-sales telephone: 086-523-88858618

Sales hotline: 008615061040941

Email: ailian@bluepurell.com

Address: No. 88 Xingjiang Road, Jiangyan District, Taizhou City, Jiangsu Province

Language

Language