Screw pumps

All copper high-temperature resistant lacquer wire with thermal protector, double protection to prevent burnout.

Product Category

key word:

Screw pumps

Detailed Description

| Product Information | |||||

| Order Number | Screw pumps | Type | Screw pumps | Item No. | Screw pumps |

| Brands | Dawei Environmental Protection | Model | Screw pumps | Material | Carbon Steel |

| Drive method | Electric | Performance | Health | Uses | Sewage pumps |

| Conveying medium | Sewage pumps, impurity pumps | Pump shaft position | Side vertical | Number of impellers | Multi-level |

| Flow | /(m3/h) | Lift | 60-300(m) | Rotational Speed | 400-720(rpm) |

| Suction caliber | 25-200(mm) | Discharge diameter | 25-250(mm) | Efficiency | / |

| Output Flow | 0.8-150 | Weight | 50(kg) | Voltage | 0.6/1.2(V) |

| Power | Selected by specific gravity and viscosity of the liquid (kw) | Whether the cross-border export of exclusive sources of goods | No | ||

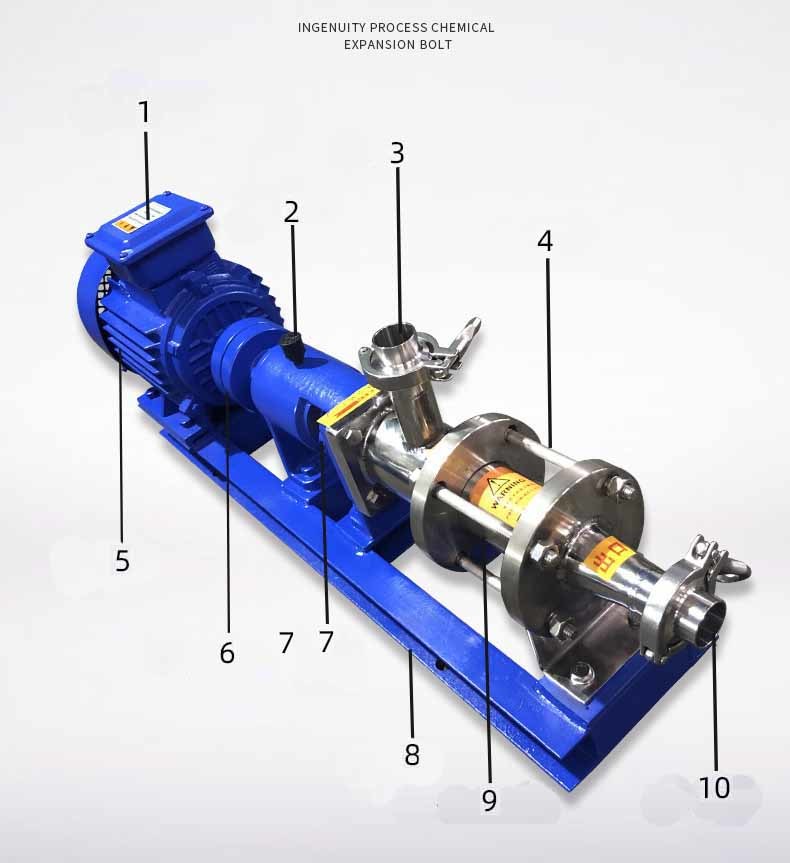

| Product Structure Analysis | ||

| 1 Junction Box | 2 Lube oil filling hole | 3 Import |

| 4 Tie Rod | 5 Motor | 6 Couplings |

| 7 Packing gland | 8 Base | 9 Stator Rotor |

| 10 Export | ||

| Details | ||

|

|

|

|

All brass movement |

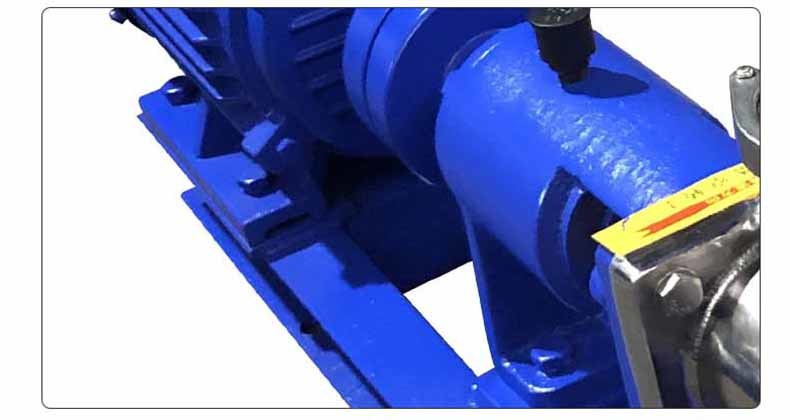

Visible quality | Thickened base |

| All copper high-temperature resistant lacquer wire with thermal protector, double protection to prevent burnout. | The surface is made by special process, smooth surface and excellent sealing. | Thickening installation fixed, seismic and smooth operation, quality assurance. |

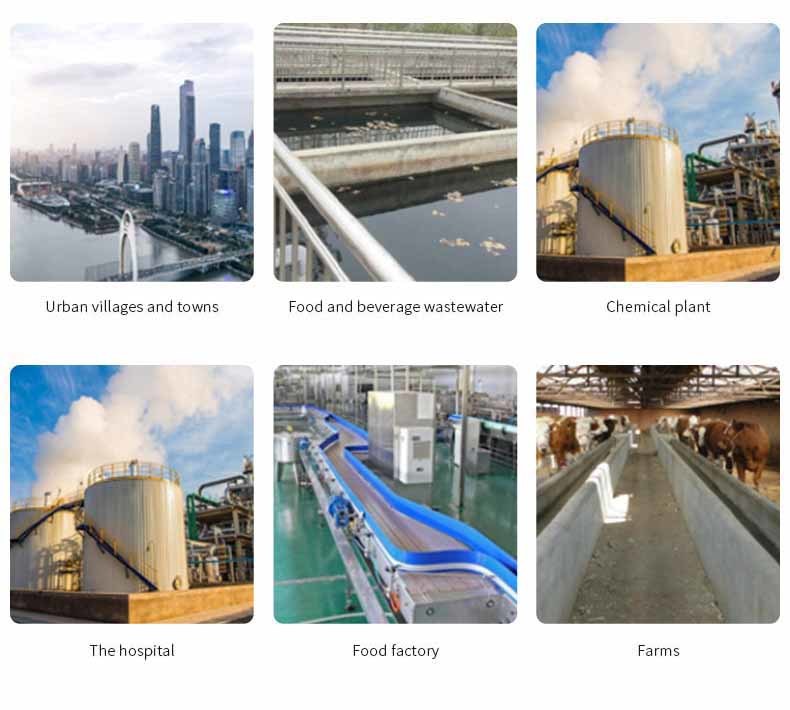

Products are suitable for a variety of applications

| Product parameters | |

| Brand: Dawei Environmental Protection | Material: Cast iron |

| Name: Screw pump | Drive mode: Electric |

| Head(M): 60-300 | Use: Impurity pump |

| Conveying medium: various viscous pulp, cement sand pump, lime, etc. | |

| Motor power: selected according to the specific gravity and viscosity of the liquid | |

、、

、、

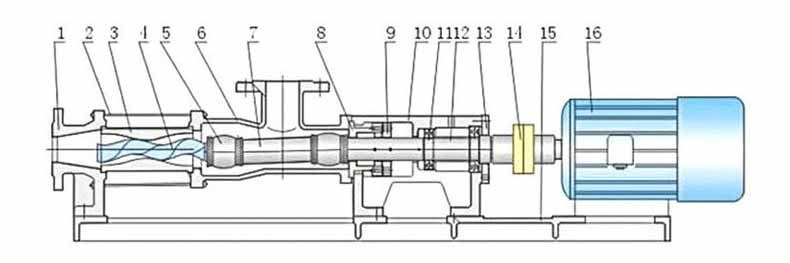

| Product structure diagram | ||||||||

| Serial number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Name | Discharge body | Tie Rods | Stator | Screw shaft | Universal joint or pin connection | Feed body | Connection shaft | Packing seat |

| Serial number | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Name | Packing gland | Bearing Housing | Bearings | Drive Shaft | Bearing cover | Couplings | Base | Motor |

| Technical parameters | ||||||||

| Model | Rotational speed (r/min) | Flow rate (m3/h) | Pressure (MPa) | Motor (kw) | Head (m) | Import (mm) | Outlet (mm) | Allowable particle diameter (mm) |

| G20-1 | 960 | 0.8 | 0.6 | 0.75 | 60 | 25 | 25 | 1.5 |

| G20-2 | 960 | 0.8 | 0.6 | 1.1 | 120 | 25 | 25 | 1.5 |

| G25-1 | 960 | 2 | 0.6 | 1.5 | 60 | 32 | 25 | 2 |

| G25-2 | 960 | 2 | 1.2 | 2.2 | 120 | 32 | 25 | 2 |

| G30-1 | 960 | 5 | 0.6 | 2.2 | 60 | 50 | 40 | 2.5 |

| G30-2 | 960 | 5 | 1.2 | 3.0 | 120 | 50 | 40 | 2.5 |

| G35-1 | 960 | 8 | 0.6 | 3.0 | 60 | 65 | 50 | 3 |

| G35-2 | 960 | 8 | 1.2 | 4.0 | 120 | 65 | 50 | 3 |

| G40-1 | 960 | 12 | 0.6 | 4.0 | 60 | 80 | 65 | 3.8 |

| G40-2 | 960 | 12 | 1.2 | 5.5 | 120 | 80 | 65 | 3.8 |

| G50-1 | 960 | 20 | 0.6 | 5.5 | 60 | 100 | 80 | 5 |

| G50-2 | 960 | 20 | 1.2 | 7.5 | 120 | 100 | 80 | 5 |

| G60-1 | 960 | 30 | 0.6 | 11 | 60 | 125 | 100 | 6 |

| G60-2 | 720 | 30 | 1.2 | 11 | 120 | 125 | 100 | 6 |

| G70-1 | 720 | 45 | 0.6 | 11 | 60 | 150 | 120 | 8 |

| G70-2 | 720 | 45 | 1.2 | 15 | 120 | 150 | 120 | 8 |

| G85-1 | 720 | 60 | 0.6 | 18.5 | 60 | 150 | 150 | 10 |

| G105-1 | 500 | 100 | 0.6 | 22 | 60 | 200 | 200 | 15 |

| G135-1 | 400 | 150 | 0.6 | 37 | 60 | 200 | 250 | 20 |

Recommended Products

Online Mssage

Contact

National after-sales telephone: 086-523-88858618

Sales hotline: 008615061040941

Email: ailian@bluepurell.com

Address: No. 88 Xingjiang Road, Jiangyan District, Taizhou City, Jiangsu Province

Language

Language