In recent years, environmental pollution has reached a small peak, and the national requirements for environmental protection standards have become increasingly strict. Chemical pollution has become the most serious source of industrial water pollution in China. Rivers near many chemical plants are seriously polluted, looking like a dead river, accompanied by a pungent smell. In the process of production, chemical plants will carry some suspended impurities, which will become sludge after a certain time of precipitation. Sludge polluted by chemical sewage, as well as a large number of bacteria, various excessive heavy metals, parasites and many harmful substances that are difficult to degrade, will indirectly affect our health.

Most of the early sludge treatment methods in China are incineration, composting, landfill, etc. However, due to the particularity of chemical sludge, the above methods are not suitable. Chemical sludge has small particles and high moisture content, so it is not easy to treat. Therefore, as a dehydration equipment more suitable for chemical sludge treatment, the screw type sludge dehydrator (hereinafter referred to as the "screw type sludge dehydrator") came into being. After dewatered by Dawei Environmental Protection screw type sludge dehydrator, the water content of the sludge can be reduced to below 75%, which can greatly reduce the sludge volume and transportation costs.

There are two main steps for the dehydration of chemical sludge by the screw stacker: dosing flocculation and mechanical main body dehydration.

-

Flocculation

Dosing flocculation makes use of the characteristics of sludge with negative ions. By adding flocculants, positive and negative charges will react in the muddy water, forming large flocs like alum, so that the sludge particles in the muddy water can be rapidly destabilized, which is the best way to accelerate the settling speed. By using the adsorption bridging function, the colloid in the sewage is fundamentally reduced to about half of the original. On the one hand, it can improve the settling speed, while on the other hand, it is a key factor to affect the subsequent sludge treatment effect that the PH value in the sludge can be adjusted to an interval suitable for sludge dewatering. Dawei Environmental Friendly Tip: The staff needs to carefully observe the sedimentation and agglomeration effect before the sludge enters the main body for dehydration.

-

Main body dehydration

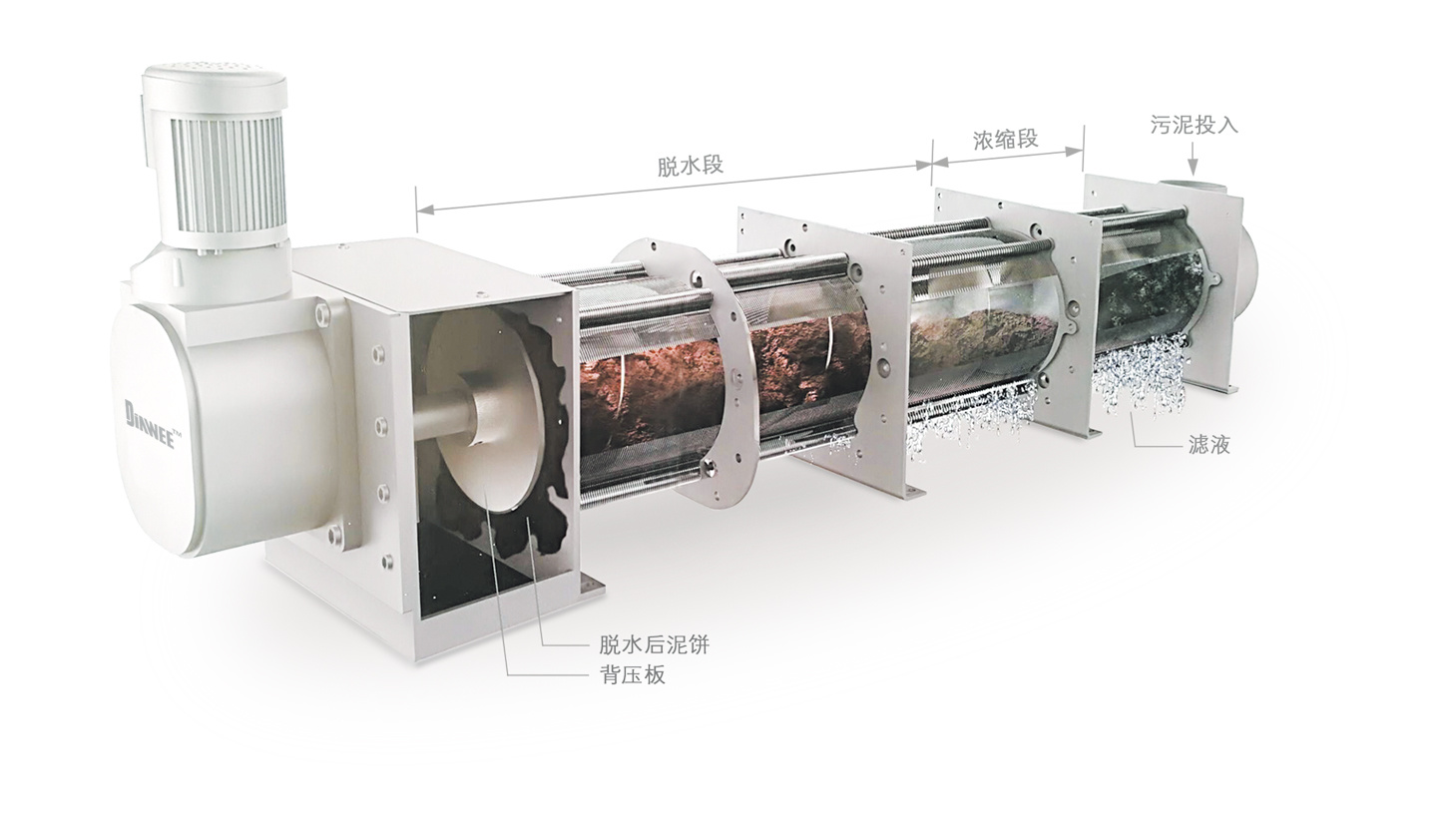

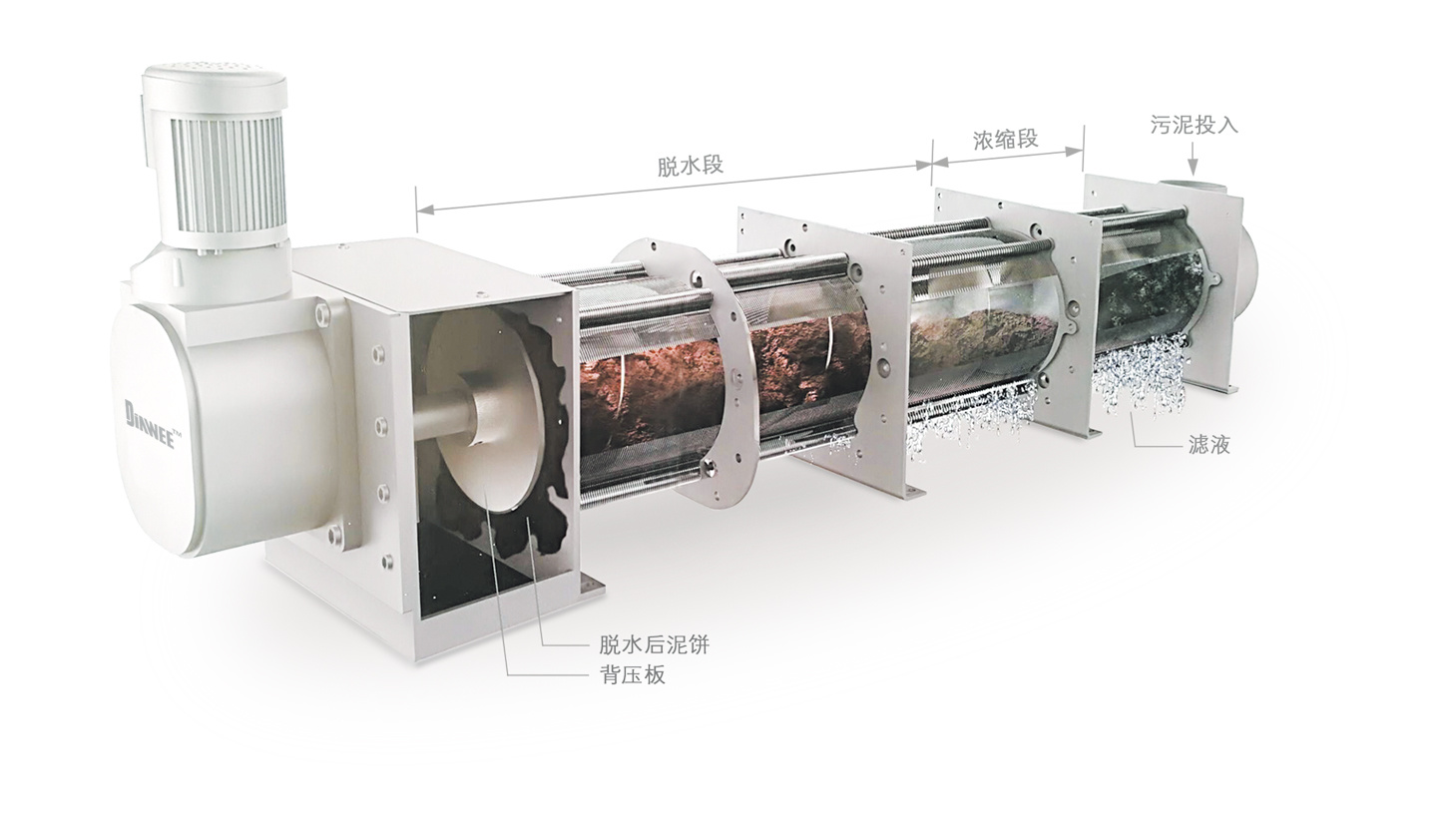

The concentrated mud continues to move forward with the rotation of the spiral shaft of the screw stacker body. Along the outlet direction of the mud cake, the screw pitch of the spiral axis is smaller and smaller, the space between the rings is smaller and smaller, and the volume of the spiral cavity is shrinking. Under the action of the back pressure plate at the outlet, the internal pressure gradually becomes stronger, the propulsion shaft moves in turn, the water in the mud is squeezed out, the solid content of the filter cake continues to increase, and finally the mud is continuously dehydrated. The dewatering technology of the main part of the screw stacker can make the sludge fully concentrated and optimize the sludge dewatering performance, so it is widely used in chemical plants.

Although this is a good method for sludge dewatering effect, in view of the huge cost of purchasing a large number of equipment and requiring a large number of operators, this method cannot completely replace the traditional sewage treatment technology, but automatic sludge dewatering treatment is bound to become the future direction of chemical wastewater treatment.

In the process of chemical sludge treatment, there are usually some refractory substances and microbial residues. The water content can be reduced through the dehydration of the screw stacker, so as to reduce the sludge, reduce the final disposal cost and sludge difficulty. With the continuous strengthening of environmental protection, the requirements for the treatment of chemical sludge are becoming higher and higher. Natural drying cannot guarantee the treatment efficiency and quality of chemical sludge. Therefore, the screw type sludge dehydrator, which can save energy and electricity, is simple to maintain, and can operate automatically without people for a long time, is very suitable for sewage and sludge in the chemical industry.

Language

Language